In the landscape of small-scale metal fabrication, low-volume production runs—whether for custom orders, prototype development, or niche market demands—present unique challenges. Small fabricators often operate with limited space, tight budgets, and the need to adapt quickly to diverse customer requirements, all while maintaining precision and cost-effectiveness. Among the array of forming technologies available, IO forming machines have emerged as the preferred choice for these operations, offering a perfect balance of flexibility, efficiency, and accessibility that aligns with the needs of low-volume production. For small fabricators aiming to compete without sacrificing quality, IO forming machines have become an indispensable tool for turning niche opportunities into profitable outcomes.

Low-volume runs in small fabrication shops are defined by their variability: one project may involve forming stainless steel tubes for custom furniture, the next aluminum components for automotive prototypes, or copper tubing for specialized HVAC systems. Traditional forming methods—such as manual bending, basic mechanical presses, or large-scale industrial equipment—struggle to accommodate this diversity. Manual processes lack precision and consistency, leading to high defect rates and material waste that eat into profit margins for small-batch orders. Industrial-grade machines, while powerful, are prohibitively large, expensive, and complex for small shops, requiring significant upfront investment, dedicated floor space, and specialized training to operate. For small fabricators, these barriers often make low-volume runs inefficient or unprofitable, limiting their ability to serve niche markets or take on custom projects.

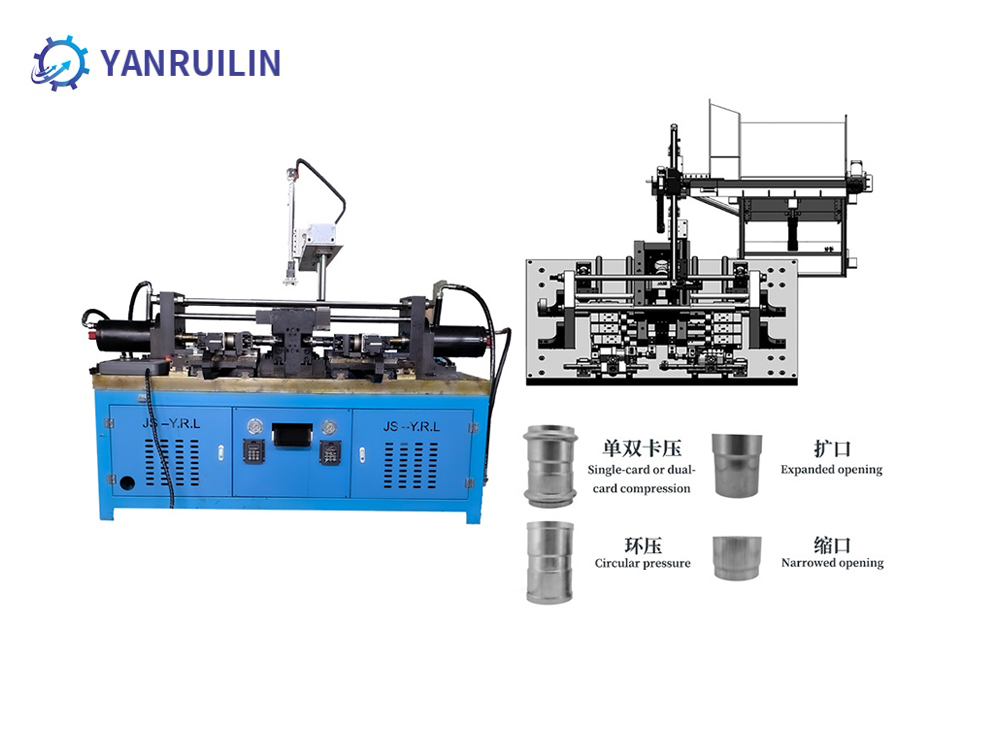

IO forming machines address these pain points by prioritizing flexibility and adaptability—core requirements for low-volume production. Unlike traditional equipment that is often specialized for a single task or material, IO machines are designed to handle a wide range of tube sizes, materials, and forming profiles with minimal reconfiguration. Quick-change tooling systems allow operators to switch between forming tasks—such as flaring, beading, swaging, or custom profiling—in minutes, eliminating the downtime associated with retooling larger machines. This versatility enables small fabricators to take on diverse low-volume projects without investing in multiple specialized tools, expanding their service offerings and opening doors to new customer segments. Whether forming thin-walled aluminum tubes for medical devices or thick-walled steel pipes for industrial fittings, IO machines adapt seamlessly to varying requirements.

Cost-effectiveness is another key reason small fabricators favor IO forming machines for low-volume runs. Traditional industrial forming equipment comes with high upfront costs that are difficult to justify for small-batch production, where revenue per project is often limited. IO machines, by contrast, are available in compact, budget-friendly models that deliver professional-grade performance without the premium price tag. Their energy-efficient designs—often consuming 30-50% less power than larger hydraulic or mechanical machines—reduce ongoing operational costs, a critical advantage for small shops operating on tight budgets. Additionally, IO machines minimize material waste through precise forming and consistent results, cutting down on raw material expenses that can disproportionately impact low-volume runs. For small fabricators, this combination of lower upfront investment, reduced operational costs, and minimal waste makes low-volume projects financially viable.

Ease of use and accessibility further solidify IO forming machines as the ideal choice for small fabricators. Unlike complex industrial systems that require extensive training or skilled operators, IO machines feature intuitive touchscreen controls, pre-loaded forming templates, and simplified programming. Operators with basic technical knowledge can quickly input project specifications, adjust parameters, and launch production—eliminating the need for costly specialized labor. This accessibility empowers small shop owners and their teams to handle low-volume runs independently, without outsourcing or hiring additional staff. For small fabricators with limited resources, this ability to streamline operations and reduce labor costs is a game-changer, making it easier to manage variable workloads and maintain profitability.

Precision and consistency are non-negotiable even in low-volume production, as custom orders and prototypes often require tight dimensional tolerances to meet customer specifications. IO forming machines deliver micron-level accuracy through servo-driven systems, advanced sensors, and CNC integration. Unlike manual methods that are prone to human error, IO machines execute forming sequences with repeatable precision, ensuring every component in a low-volume run meets exact standards. Real-time process monitoring and automatic error correction features further enhance quality control, reducing the need for rework and ensuring customer satisfaction. For small fabricators, this level of precision allows them to compete with larger manufacturers, even on custom or niche projects where quality is paramount.

Compact design is a critical advantage for small fabricators operating in limited space—such as garage-based shops or small industrial units. IO forming machines feature a streamlined footprint, often 50-70% smaller than traditional industrial forming equipment, making them easy to integrate into tight workspaces. Their compact size does not compromise performance, however; even smaller IO models deliver sufficient force to form a wide range of materials, from soft copper to high-strength alloys. This space efficiency enables small fabricators to maximize their production capacity without expanding their facilities, a cost-saving benefit that aligns with the constraints of low-volume operations.

As the demand for custom, low-volume metal components continues to grow—driven by industries such as aerospace, medical devices, and renewable energy—small fabricators are increasingly turning to IO forming machines to meet market needs. These machines empower small shops to compete with larger manufacturers by offering the flexibility to handle diverse projects, the cost-effectiveness to maintain profitability, and the precision to deliver high-quality results. For small fabricators, IO forming machines are more than just equipment—they are a strategic tool that levels the playing field, enabling them to thrive in a market where agility and adaptability are key to success.

In a sector where low-volume runs were once seen as a challenge, IO forming machines have turned them into an opportunity. By combining versatility, cost-effectiveness, ease of use, and precision, these advanced systems enable small fabricators to take on custom projects, serve niche markets, and grow their businesses—all while maintaining the high standards that customers demand. As manufacturing technology continues to evolve, IO forming machines will remain the preferred choice for small fabricators looking to unlock the potential of low-volume production and build sustainable, profitable operations.

Diese Website verwendet Cookies, um sicherzustellen, dass Sie das beste Erlebnis auf unserer Website erhalten.

Kommentar

(0)